- Home

- Resources

- ANSI ISEA Safety Standards

- ANSI ISEA Cut Levels

ANSI ISEA Cut Levels

ANSI/ISEA 105 CUT LEVELS

Standard for Cut Testing

The American National Standards Institute (ANSI) and International Safety Equipment Association (ISEA) current standard for displaying the rating of hand protection against cut risks is ASTM F2992-15.

ASTM F2992-15 Standard

- 9 Levels of cut protection

- TDM-100 is the only machine acceptable for testing

- Blade must be changed after each test

- 5 times at each of 3 weight loads ensure accurate results

ASTM F2992-15 is the standard used to obtain gram results, the ANSI/ISEA 105-2023 standard then interprets what classification level those results will report as. These two standards streamline the process, ensuring predictability and consistency across the hand protection industry.

ANSI/ISEA 105-2023 New Icon Designation

Current Cut Levels

| Cut Level | HAZARDS |

| Level A1 | Assembly, Warehouse, Material Handling |

| Level A2 | Automotive, Packaging, Metal Handling |

| Level A3 | Construction, Automotive Assembly |

| Level A4 | Glass Handling, HVAC, Machining, Metal Fabrication |

| Level A5 | Appliance Manufacturing, Glass Handling, HVAC |

| Level A6 | Metal Stamping and Fabrication, Electrical, Construction |

| Level A7 | Aerospace, Window Manufacturing, Recycling |

| Level A8 | Very high cut risks, Aerospace, Recycling |

| Level A9 | Highest cut risks |

Timeline of Cut Resistance Standards

In 1997 the first cut resistant standard, ASTM F1790, is introduced for hand protection. It used a CPPT machine. The standard is revised in 2005, using a TDM-100 machine approved to use in addition to CPPT machine. The standard is revised again in 2014, due to consistency issues between test results. In 2016, the newest standard, ASTM F2992-15, is adopted by ANSI/ISEA that only uses the TDM-100 machine

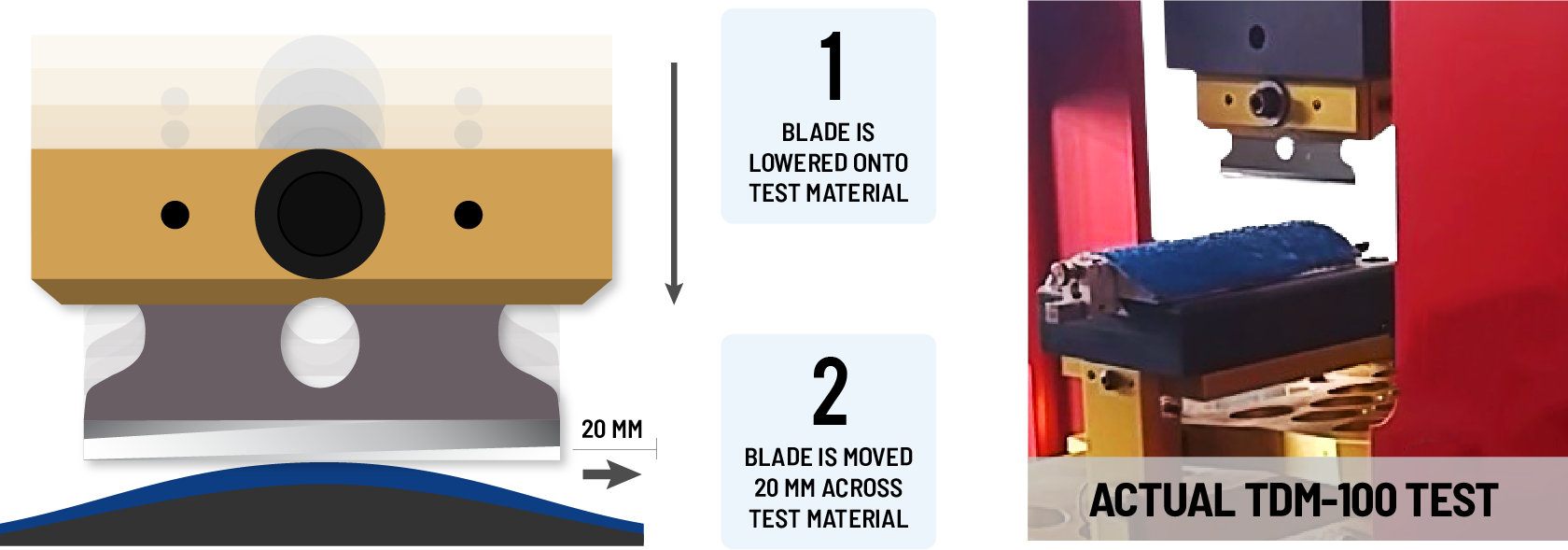

The TDM-100 Machine Cut Test

- Material from the product to be tested is fitted to the base of the TDM-100 testing machine (blue in illustration).

- A specific weight is applied to the new razor blade, which is lowered to the material. The motor draws the blade with the applied weight across the material until cut through occurs. The number of mm to cut-through is reported for that weight.

- The weight loads are repeated 5 times to provide 15 data-points for cut-through at short, medium, and long blade travel.

- A liner regression of all 15 data-points provides the calculated weight in grams where the 20 mm blade travel would occur. Three samples are tested for each material for a total of 45 data-points to determine the weight (grams).

- ANSI/ISEA 105-2016 Hand Protection Performance Classification is applied to provide the level based on the gram weight of cut through with 20 mm blade travel.